Goal of this project is to produce a Bionic Hand or a Mechanical Hand that is affordable and accessible by everyone of any class while retaining their degree of reliability for perfect daily use. This is the second generation of project based around the topic of Bionic Hand in university, but the first one that was made from scratch and brought to life.This project is also documented by national news called Detik. There are few articles regarding this project, listed down below.

Objective

Creating a required project by Swiss German University based on research made by lecturers or seniors.

Action

Researching and crafting hypotheses related to the topic

Designing machine using Solidworks

Choosing electrical component that complements the design and the goal

Creating a program for the user to be able to move the hand

Testing for reliability and future upgrades

Result

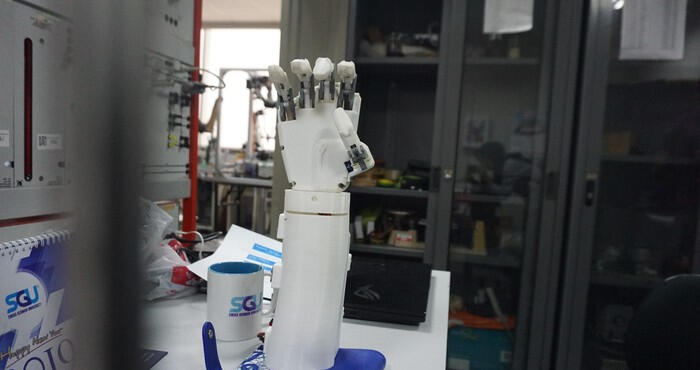

Created a fully working, low cost, accessible and reliable bionic hand.

Background

There are at least hundreds of people in Indonesia who are in need of a mechanical hand, or more known as Bionic Hand. However, the cost to require one is immensely high and it is hard even for the higher society to procure one due to the cost. This project is targeted for the less fortunate people to be able to get their hands on one, at a very reasonable cost with equivalent quality of product. The result of this research will help in moving the scientists and inventors of Indonesia into the world of prosthetics, in order to developing them. The features of this project involve the development of design in mechanical and electrical engineering which allows the prosthetic to be able to move the fingers individually.

Project Overview

WHAT IS USED TO RECEIVE MUSCLE SIGNAL?This is the Myo Armband created by Thalmic Labs, a muscle sensory device which is used as the input signal. Unfortunately, this item is very limited and took up most of the budget for the project.

WHAT DOES THE MACHINE RUN ON?The power source of this arm is a Lithium Polymer battery, which has to be charged occasionally. However, the dimension and the weight of this battery can be a problem for the user since it is quite large.

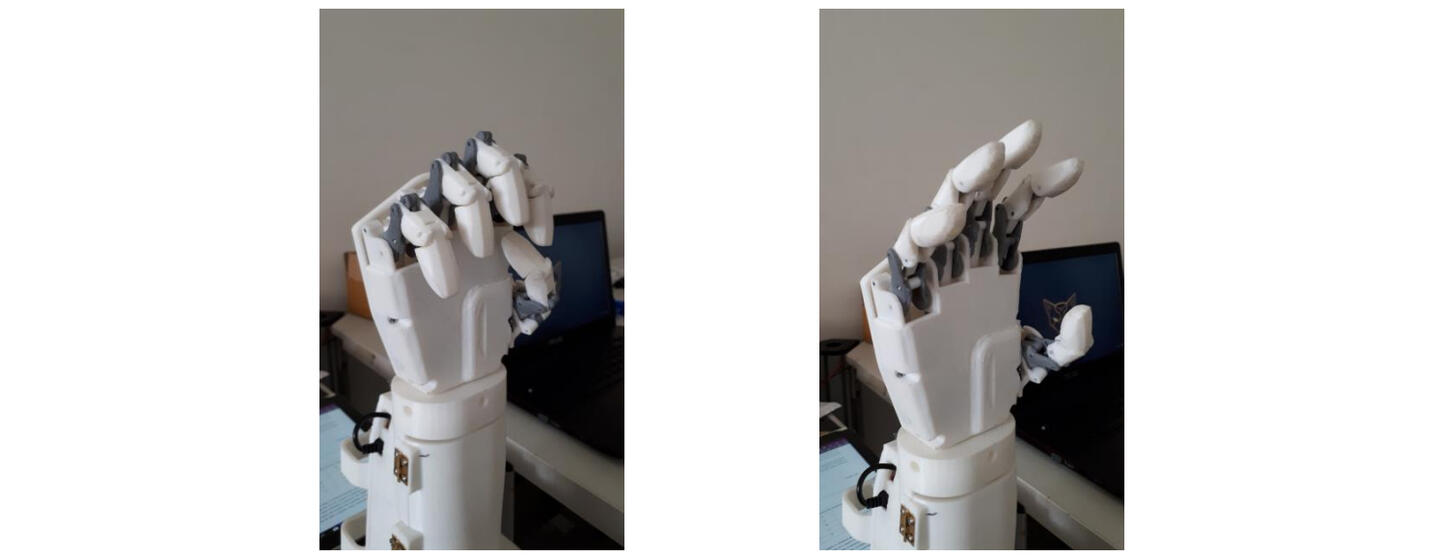

CAN THE ARM CREATE HUMANE GESTURES?Yes, but as for now the arm can only replicate 4 human gestures shown in the picture. These are the default gestures that can perfectly be received by the Myo Armband. Any further gestures require machine learning or AI to be implemented into the program itself.

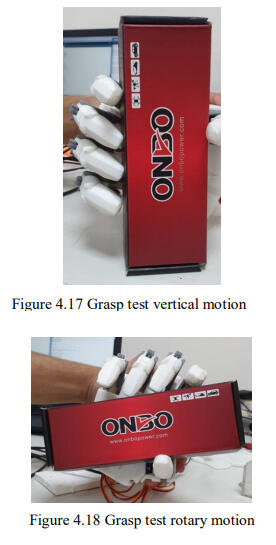

CAN IT LIFT OBJECTS LIKE ANY HUMAN WOULD?Yes! However, there are limitations on the shape and weight that the arm can lift as of this development. This is caused of the limited motion within the joints of the arm, and the surface of the fingers are considerably smooth enough and does not have enough grip or friction force to withhold the objects.

WHAT HAPPENS IF WE LIFT HEAVY OBJECTS USING THE ARM?The shaft of the motor inside will break, with possible damage to the gears inside the mechanism. Luckily, the motors can be commonly found and can be replaced with little cost. There are cases where the "bones" that connects the motor to the finger joints will break due to the heavy force inflicted on it.

Final Verdict

The arm is working as intended, and the cost required to build the current version is considerably cheap. It can perform 4 different basic gestures. Additionally, it can lift objects with cubical or spherical shape, with a maximum weight of 200 grams.

For further upgrades, several suggestions are listed below:

Looking for different sensory device that can be obtained easily at a very low cost, or create a sensory device.

Upgrade the programming by implementing Machine Learning in order for the arm to perform additional motion or gestures.

Optional, but reduce the size of the battery since it is where most of the weight is stored.

Gallery

Click on the icons below to get a full overview of the documented project.